News

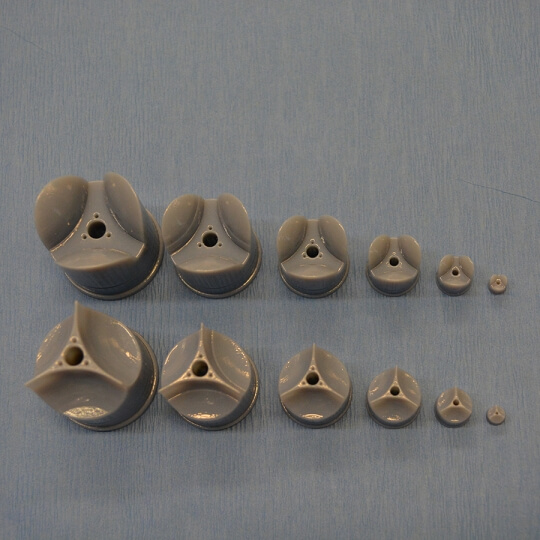

In rotary jet spinning technology, a rotating nozzle extrudes a solution of extracellular matrix (ECM) into nanofibers that wrap themselves around heart valve-shaped mandrels. By using a series of mandrels with different sizes, the manufacturing process becomes fully scalable and is able to provide JetValves for all age groups and heart sizes. (Photo courtesy of Wyss Institute at Harvard University)

The human heart beats approximately 35 million times every year, pumping blood via four different heart valves. Unfortunately, in more four million people each year, these delicate tissues malfunction due to birth defects, age-related deteriorations, and infections causing cardiac valve disease.

Today, clinicians use either artificial prostheses or fixed animal and cadaver-sourced tissues to replace defective valves. While these prostheses can restore the function of the heart for a while, they are associated with adverse comorbidity and wear down and need to be replaced during invasive and expensive surgeries. Moreover, in children, implanted heart valve prostheses need to be replaced even more often as they cannot grow with the child.

A team lead by Kevin Kit Parker, Tarr Family Professor of Bioengineering and Applied Physics at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), recently developed a nanofiber fabrication technique to rapidly manufacture heart valves with regenerative and growth potential.

Parker is also a Core Faculty member of Wyss Institute for Biologically Inspired Engineering at Harvard University.

In a paper published in Biomaterials, first author Andrew Capulli and colleagues fabricated a valve-shaped nanofiber network that mimics the mechanical and chemical properties of the native valve extracellular matrix (ECM). The team used the Parker lab’s proprietary rotary jet spinning technology – in which a rotating nozzle extrudes an ECM solution into nanofibers that wrap themselves around heart valve-shaped mandrels.

“Our setup is like a very fast cotton candy machine that can spin a range of synthetic and natural occurring materials,” said Parker. “In this study, we used a combination of synthetic polymers and ECM proteins to fabricate biocompatible JetValves that are hemodynamically competent upon implantation and support cell migration and re-population in vitro. Importantly, we can make human-sized JetValves in minutes – much faster than possible for other regenerative prostheses.”

To further develop and test the clinical potential of JetValves, Parker’s team partnered with the translational team of Simon P. Hoerstrup, at the University of Zurich. As a leader in regenerative heart prostheses, Hoerstrup and his team in Zurich previously developed regenerative, tissue-engineered heart valves to replace mechanical and fixed-tissue heart valves. In Hoerstrup’s approach, human cells directly deposit a regenerative layer of complex ECM on biodegradable scaffolds shaped as heart valves and vessels. The living cells are then eliminated from the scaffolds resulting in an “off-the-shelf” human matrix-based prostheses ready for implantation.

In the paper, the cross-disciplinary team successfully implanted JetValves in sheep using a minimally invasive technique and demonstrated that the valves functioned properly in the circulation and regenerated new tissue.

“In our previous studies, the cell-derived ECM-coated scaffolds could recruit cells from the receiving animal’s heart and support cell proliferation, matrix remodeling, tissue regeneration, and even animal growth. While these valves are safe and effective, their manufacturing remains complex and expensive as human cells must be cultured for a long time under heavily regulated conditions. The JetValve’s much faster manufacturing process can be a game-changer in this respect. If we can replicate these results in humans, this technology could have invaluable benefits in minimizing the number of pediatric re-operations,” said Hoerstrup.

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Kit Parker

Tarr Family Professor of Bioengineering and Applied Physics

Press Contact

Leah Burrows | 617-496-1351 | lburrows@seas.harvard.edu