News

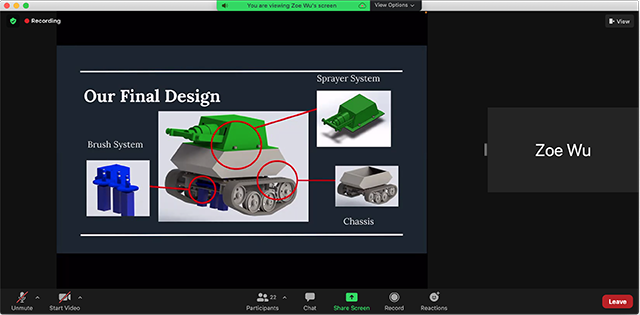

Students Zoe Wu and and Carlos Gutierrez present their final project in ES 51, a robotic tank that uses its barrel to spray sanitizer on a phone.

In a typical year, the last few days of the fall term are a whirlwind of activity for students in “Computer Aided Machine Design” (ES 51) as they scramble to put the finishing touches on their remote-controlled robots in time for the course-culminating mechanized melee.

2020 has not been a typical year.

With most students logging into virtual class from their homes and without access to the 3D printers, laser cutters, milling machines, and abundance of tools available in the Active Learning Labs, they and their instructors had to get creative.

“For the final project, we challenged students to come up with an idea to solve a problem in their everyday lives,” said instructor Michelle Rosen, Lecturer in Mechanical Engineering Design. “I told them to make a robot that will do something that you are too lazy to get up off the couch to do.”

The students had some help from Mechanical Engineer for Active Learning Tony Turner (as well as from FedEx). At the start of the course, Turner prepared and shipped to the students packages that contained a basic, remote-controlled robot kit, tools and components for some course labs, and items like a plywood peg board covered with holes that students could customize for their final projects,.

The students were tasked with modifying that basic robot for their final project.

After forming teams and designing their projects using CAD software, the students submitted orders to Turner for customized parts, which he crafted using laser cutters and 3D printers. Turner ultimately prepped and shipped to students hundreds of parts on a short deadline.

“It would have been really easy to send them all Lego kits, but that is not what this course is about,” he said. “We emphasized modular design and adaptability, because if their design didn’t work, we wouldn’t be able to send them any more parts due to time constraints. We guided them through really thinking about how to solve problems with limited resources and change their designs slightly with some tools that we gave them.”

First-year student Zoe Wu and her teammate appreciated Turner’s quick turnaround—they received the custom parts for their project, a robotic tank that uses its barrel to spray sanitizer on a phone, two days after placing the order.

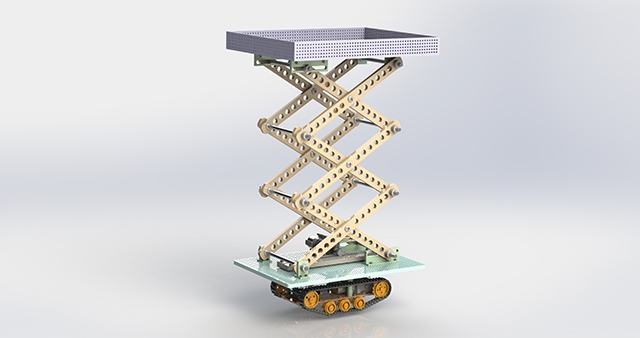

Egemen Bostan and his teammates developed this robotic tray that can drive and move up and down.

The biggest challenge they faced was designing those parts using SolidWorks and collaborating via Zoom to hammer out the complex subsystems that enabled their robot to scrub a phone screen with brushes hanging underneath its chassis.

“I come from an arts background, so I’ve been having fun trying to bridge the gap between functionality and appearance,” she said. “This project has taught me that, in engineering, it is so important to plan and think and design before you actually start prototyping.”

Planning and designing in SolidWorks was all Egemen Bostan was able to do for his team’s final project, after customs complications prevented the supply kit from reaching his home in Turkey.

Bostan and his partners developed a robotic tray that could roll from the fridge loaded with snacks and then rise to desk-level to serve a hungry, hard-working student. He learned a great deal about designing components using SolidWorks, and further developed collaborative skills that will come in handy during future engineering courses.

“This course has taught me to look at things like a mechanical engineer,” said Bostan, S.B. ’22, a mechanical engineering concentrator. “I now see the mechanical parts all around me. Knowing what they are and what they are used for, and understanding their mechanisms, gives me ideas to improve them. Developing a language for ideas was a very big part of this class for me.”

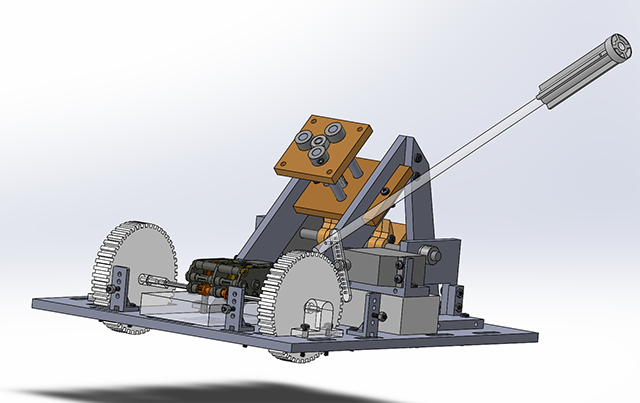

Having the freedom to turn their ideas into reality was rewarding, but also very challenging, said first-year student Andres Hernandez Gonzalez. He and his teammates designed a robot that could play with a pet by oscillating a chew toy and launching a tennis ball for a mechanical game of fetch.

Andres Gonzalez and his teammates designed this robot to play with a pet by oscillating a chew toy and launching a tennis ball.

A major challenge Gonzalez faced was developing the complex piston and spring assembly. Designing the custom support brackets was especially tough, since they had to be flush with the robot’s base plate, but also stand at a 45-degree angle.

“The biggest lesson I learned from this is the importance of cooperation. I don’t know all the answers. Working together can give you a better perspective of what you can do,” he said. “Cooperating with others puts you in a better position to learn.”

Working together in a remote environment is a valuable lesson for budding engineers, Rosen said. Professional engineers often collaborate with colleagues around the world on complicated projects with many separate subsystems.

One silver lining of teaching the class remotely was a noticeable boost in students’ problem-solving skills, she said.

For Rosen, who “flipped” her classroom by recording lectures for students to watch and focusing more on collaborative problem solving during class time, this iteration of ES 51 has been a valuable learning experience, too.

“This semester, the students had to be somewhat creative. What do you have around your house you can use? Typically, students tend to see things in the lab, or we watch a video, but I want to encourage them to really look at the things around them,” she said. “This has been really fun and eye-opening for me. When we started this, I had no idea what they were going to come up with.”

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu