News

Where there’s a college campus, there are people and where there are people, there are rats.

Rodents can pose a public health risk, as well as cause damage that leads to increased maintenance and repair costs to facilities and equipment on campus.

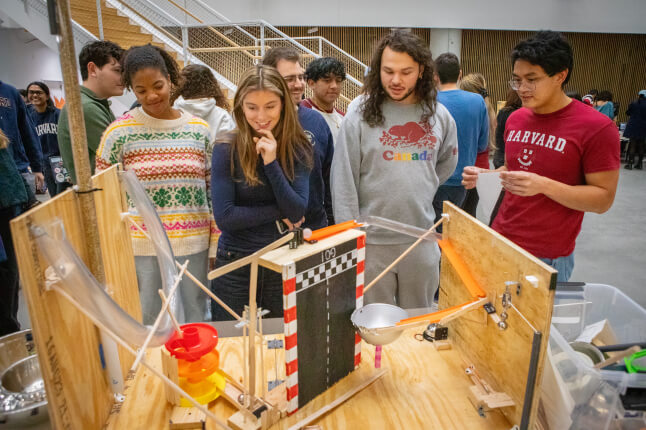

A group of third-year students developed methods to track and reduce rat sightings on campus for ES96: Engineering Problem Solving and Design Project. Top row from left: Tripp Carolan, Egshiglen Chuluunhuu, Kian Abbott, Caleb Moore and instructors Jenn Yoolim Kim and Jeffrey Paten. Bottom row: Julie Alarifi, Will Sorenson, Dania Maraliz Villafuerte and Aaron Chin. (Matt Goisman/SEAS)

Harvard Environmental Health & Safety (EH&S) tasked third-year students at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) with researching “the prevention and reduction of pests on campus, helping to enhance the living and working conditions for all members of the Harvard community.” EH&S served as the client for 10 students taking ES96: Engineering Problem Solving and Design Project, a required third-year course for S.B. students in which they spend a semester researching an open-ended and complex problem and designing a plausible solution.

The 10 members of the student team were Kian Abbott, Julie Alarifi, Egemen Bostan, Tripp Carolan, Aaron Chin, Egshiglen Chuluunhuu, Mike Doggett, Caleb Moore, Will Sorenson and Dania Maraliz Villafuerte.

“The unique part of ES96 is that a large part of the effort is defining the problem itself, and then finding where an intervention needs to be placed,” said Chuluunhuu. “We didn’t want to just use the skills we had to build something for the sake of building something. We wanted to make sure a clear definition of the problem informed how we approached the solution.”

The ES96 team ended up with a three-part solution: a new lid for campus trash cans that rats can’t chew through; a small ultrasonic device that emits a startling noise whenever rats approach; and a website that compiles and parses the numerous individual pest reports generated for various campus buildings throughout the year.

“The goal here was not to produce a product that’s ready to go at the end of the semester, but rather to think about the manifold issues involved, including behavioral, engineering and cost,” said Richard Pollack, Senior Environmental Public Health Officer at Harvard. “They demonstrated great thought, and I’m delighted.”

Designing a new lid required research into garbage can lids already on the market, as well as the jaw strength and bite dynamics of rats. The team designed, then built (using 3D printers at the Active Learning Labs), a sloped lid with a radius of curvature designed to exceed a rat’s jaw capacity and prevent it from chewing through to any food waste inside.

“All the lids on the market are generally pretty flat, and have sharp curves and corners, which seems to be what allows rodents to chew through them,” said Carolan, who was part of the sub-team that designed the “H Bin” lid. “We set out to change the geometry of the lid while still using the same low-cost materials. Looking at the maximum extension of a rodent’s jaw, we designed this to be somewhat similar to a jawbreaker candy, which would prevent them from getting purchase on it to chew through.”

Creating a new lid relied heavily on mechanical engineering but determining which buildings at campus are most at risk for rat presence required much more computer science.

Chuluunhuu and the other members of that subteam built a website, called “Pestylitics,” which could scan reports generated by the pest management vendors, then compile the information into easily accessible graphs and charts.

“A system like this can better allow us to detect changes, trends or emerging problems in a place that I might not notice for a month,” Pollack said. “The information from these tens of thousands of paper or PDF records, right now they all reside in my head. I know what’s going on in each of the buildings around campus, but that doesn’t do anybody else any good.”

The third component of the solution was the ultrasonic deterrent they called the “Scarecrow,” a battery-powered motion sensor that emits a presumptively disruptive noise, inaudible to humans, whenever a rat gets too close. Developing the Scarecrow came with its own challenges, starting with the inability to get approval for animal testing before the semester ended.

“We looked into it and realized in three years we could start testing, so we threw out that idea,” said Moore, a member of the Scarecrow team. “The hardest part was that we couldn’t necessarily validate without a lab setting. It was a lot of development, testing as best as we could, and then trying to inform our next decisions based on the testing, even if that testing didn’t necessarily give us clear conclusions.”

The experience of the Scarecrow team reflects the educational priority of ES96, which is to learn how to approach large-scale problems from a systems engineering perspective, rather than come up with a perfect solution. Students often spend the early weeks of the course researching the challenge at hand, such as what causes rat infestations, what the risks are when infestations aren’t contained, what solutions have already been attempted and how effective they’ve been.

“The course is really supposed to be about system thinking, and engineering to the point where you remove any hard stops that would keep your solution from being plausible,” said Jeff Paten, Lecturer in Engineering Sciences at SEAS and the course instructor for this section of ES96. “The actual implementation phase is more about plausibility. The emphasis of the course is really on understanding the root causes, where the intervention points are, and how to go about making a change.”

ES96 also puts SEAS students in much larger groups than most first- or second-year students have experienced, which typically means a range of engineering concentrations and skills. With that range comes a variety of potential solutions and approaches, leading to important lessons on balance and teamwork.

“It was really interesting to have to negotiate our different personalities, leadership styles and workflow styles,” Chuluunhuu said. “I was really happy to get to know my fellow engineers. We’re probably the closest group of classmates that we have among any classes that we’ve taken.”

Topics: Academics, Computer Science, Materials Science & Mechanical Engineering

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu