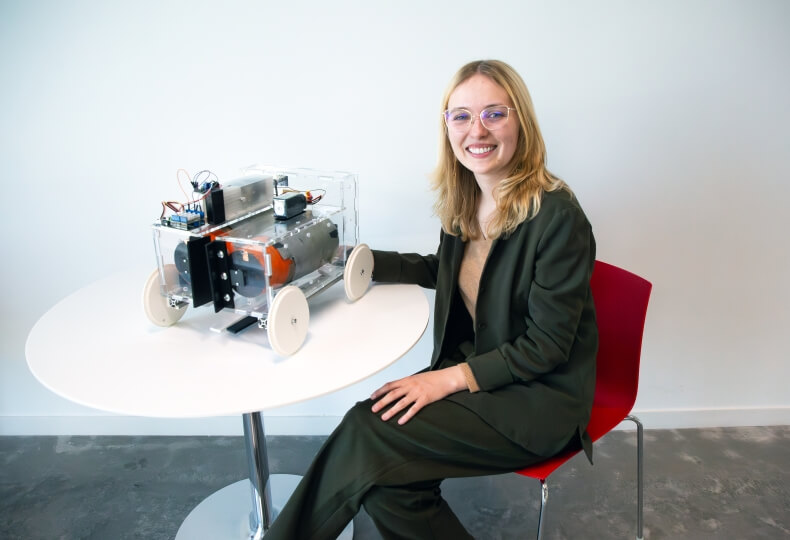

For a senior capstone project, Maycee Wieczorek built a mechanical device for controlling potato harvests (Chris Grosse/SEAS)

Engineering Design Projects (ES 100), the capstone course at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), challenges seniors to engineer a creative solution to a real-world problem.

TOTBOT: A new method for potato vine kill

Maycee Wieczorek, S.B. '24, Mechanical Engineering

Advisor: Rob Howe

• Please give a brief summary of your project.

Potato vine kill is a process that occurs in commercial potato harvesting where farmers kill the vine early to prevent disease, reduce mechanical damage during harvesting, and ensure a consistent harvest. Most potato farms use herbicides to kill vines, which is an effective method, but it is dangerous for equipment operators and the environment. Current mechanical methods of vine kill are either prohibitively expensive, or not as effective as chemical methods. My project is a mechanical method of potato vine kill that kills the potato plant by pulling the vine out of the ground while maintaining the stability of the potato bed. When tested on potato plants grown indoors, the device showed promising results in metrics of crop quality, scalability, and operational simplicity. With further development, this device can be scaled up to an affordable four-row system with a similar success rate to herbicide application that commercial potato farms can leverage in their crop management process.

• How did you come up with this idea for your final project?

I came up with the idea for this project over the summer when I was working for an agricultural engineering start-up. We were on a site visit at a farm, and some equipment operators were explaining the dangers of typical vine kill to my team. After talking with them, I saw the need for new technology in the field.

• What was the timeline of your project?

I spent around two months defining the problem, doing research into the field, considering designs, and deciding on my technical specifications. I spent the end of the first semester, around a month and a half, developing and testing my first prototype. My design phase for my final design was around two months, the build phase lasted about a month, and then the test and verify phase, with continual iteration, lasted another month.

• What part of the project proved the most challenging?

The part of the project that proved the most challenging was the testing and iteration phase. There were some commercial components that behaved unexpectedly, and troubleshooting them was a long and difficult process.

• What part of the project did you enjoy the most

I enjoyed the design phase of the project the most because it was really fun to try to take the technical specifications I had developed at the beginning of the year and design the components of the machine to match those specifications.

• What did you learn, or skills did you gain, through this project?

I learned a lot of machine design principals throughout this project. I also learned a lot about effective methods of prototyping and iterating on a design.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu