News

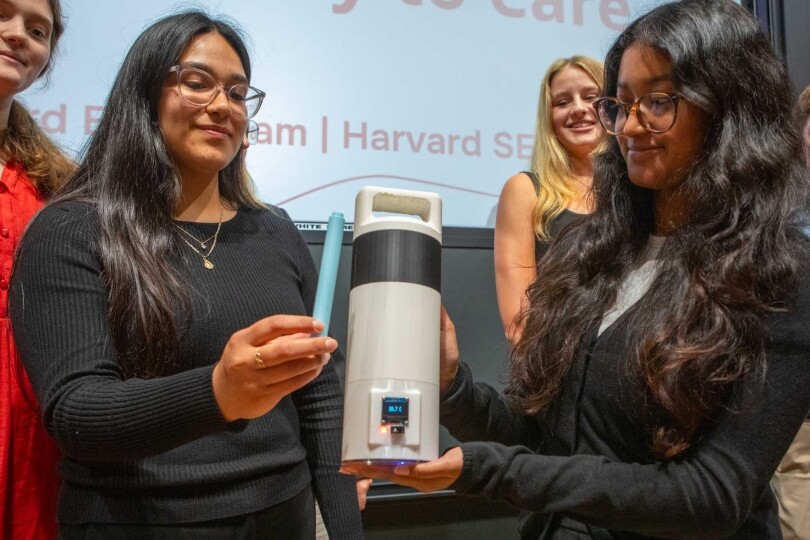

Third-year SEAS students developed a temperature-sensing cooler for last-mile drug delivery (Eliza Grinnell/SEAS)

Not all medication can be kept in your medicine cabinet. Insulin and diabetic medication, asthma biologics, certain treatments for autoimmune disorders – many drugs must be kept cool, or they go bad. And every year, billions of dollars are lost due to improper cold chain logistics as drugs go from the lab to the pharmacy to the patient.

Twelve students from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) spent this past semester developing a potential solution. Working with pharmaceutical giant Eli Lilly, the students developed TempSense, a thermos-shaped storage container capable of maintaining, monitoring and displaying its interior temperature to ensure drugs are kept at the right temperature as they’re delivered to hospitals, pharmacies or at-home users. The students designed their device for “ES96: Engineering Problem Solving and Design Project,” a core course for third-year engineering S.B. students. They were advised by Samir Mitragotri, Hiller Professor of Bioengineering and Hansjorg Wyss Professor of Biologically Inspired Engineering.

“Essentially it’s a big Yeti cooler made to store vials of drugs, and then inside are electronics,” said team leader Tolu Ademola, a mechanical engineering concentrator. “We decided to focus more on last mile delivery, which is delivery that happens after it's gone past all the pre-verification Eli Lilly monitors in the manufacturing facilities, as that’s the point where Eli Lilly doesn't have as much control over how the drugs are kept. We wanted to produce a solution that was more consumer-oriented, because we felt like that's where we could have the highest impact with the time we had.”

IDENTIFYING THE PROBLEM

A tentpole principle of ES96 is that good engineering solutions must always start with identifying a clear problem to address. Eli Lilly’s representatives, Drs. Eyal Dassau and Amit D’Souza, initially presented the students with three broad areas to potentially innovate: patients receiving the wrong doses or medications; medications being administered improperly by either medical professionals or at-home users; and maintaining the proper cold chain through to last mile delivery.

Students spent nearly six weeks researching these challenges, and decided addressing cold storage was the most feasible area to address with the remainder of the semester.

“When you're working on a project, it's really important not to get stuck on one path, but to consider multiple ways of approaching things – especially from different perspectives,” said Victoria Levy, another team leader. “We worked most effectively when we took into account where each team member was coming from. There were definitely a few times when we disagreed about what to do next, but it was still important to fully consider each idea. Even if not everyone agreed with everything, each idea had some sort of merit. Our strongest solutions came from combining ideas that brought together the widest range of perspectives.”

Twelve students worked on TempSense as their ES96 project this spring. From left: Kuma McGraw, Jiani Johnson, Victoria Levy, Elsa Oreen, Brooke Decho, Lizbeth Ibarra, Talia Vaught, Ghazal Naeimi, Mike Kuhl, Tiahna Padilla, Tolu Ademola, Ryan Novoa, Professor Samir Mitragotri, and TFs Metecan Erdi and Maham Hasib. (Eliza Grinnell/SEAS)

MECHANICAL, ELECTRICAL, AND COMMUNICATION

Once the students settled on an approach, they divided up into teams. The mechanical engineering squad designed and machined the cooler itself. The electrical engineering team worked on the temperature-monitoring electronics and display. Another team focused on communication, serving as the go-between with Eli Lilly, as well as leading preparation for the oral presentation and written report.

“One of my favorite things about ES96 was that it's very interdisciplinary between the different concentrations, so I got a chance to see how different engineers approach different problems,” said team leader Jiani Johnson. “I'm a bioengineer, so I think the way that I was approaching this problem was very different from some of the mechanical or electrical engineers. I don't do a lot of computer-aided design, but the mechanical engineers do a lot of CAD, so getting to see that process, see what it looks like and learn a little bit more about that was really good and a lot of fun.”

The end result was a lightweight cylindrical device with an interior chamber to hold the medication, which could then be surrounded by refrigerating material and insulation. A chamber in the base housed the electronics, which would display on a small organic LED screen if the temperature of the interior deviated outside of 2-8 degrees Celsius, the required range for certain classes of medication. Testing showed the device could maintain proper temperature for about 1.25 hours, but with more development time and different materials that number could be greatly enlarged.

“The beauty about mechanical engineering is that it's probably the most broad of the engineering disciplines,” Ademola said. “So even if you don't know exactly the theory behind the problem, you can definitely apply different problem solving principles to get to a solution. I liked how ES96 was a chance to meet other engineers too, because we don't normally get that in a lot of our other classes. It’s super beneficial to not just get to know other engineers in our class, but also actually solve a problem with them.”

FUTURE BENEFIT

For most SEAS students, ES96 is the largest group project they’ll take on in any of their classes. Working with so many people, and in a practical setting designed to mimic elements of working in industry, requires students to learn different skills: not just the technical skills of designing and building, but softer skills such as research, communication and collaboration.

Once they graduate, those softer skills will prove just as essential as they set out to make their mark in the world of engineering.

“I'm planning on going into industry, and as a bioengineer, a biotech company like Eli Lilly is probably where I'll end up working,” Johnson said. “It is definitely really valuable to learn how to keep company goals and priorities in mind when you're designing a solution, as well as costs and stakeholders. These are all things that we considered, and I think that's not something you typically think about in class when you're working on projects.”

Topics: Academics, Computer Science, Electrical Engineering, Health / Medicine, Materials Science & Mechanical Engineering

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu