News

Ever notice the spiral veins on tall chimneys, smokestacks, and car antennas? Those features are used to protect the structures from what's known as vortex shedding, a phenomenon that has long plagued structural engineers. Vortex shedding is a periodic swirling flow pattern that can form behind a blunt object as fluid moves past it. When these alternating zones of high and low pressure are created at intervals near the natural resonance frequency of the structure, even small amounts of wind can lead to major oscillations and cause catastrophic structural damage.

Over the years, structural engineers have employed several techniques to offset the effects of vortex shedding, including the addition of external corkscrew-like fins and other types of dampeners. But what if nature provided a better way to protect our structures from the damaging effects of vortex shedding?

These helical fins on a car antenna offset the effects of vortex shedding. (Credit: Canva)

Now, a team of researchers from Harvard University has found that the complex skeletal structure of Euplectella aspergillum, a deep-water marine sponge, can suppress vortex shedding better than many current technologies.

The research is published in Royal Society Interface.

“We found that the unique maze-like organization of external ridges in E. aspergillum can completely suppress vortex shedding, highlighting their potential benefit in various engineering contexts,” said Matheus Fernandes, a graduate student at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) and first author of the paper.

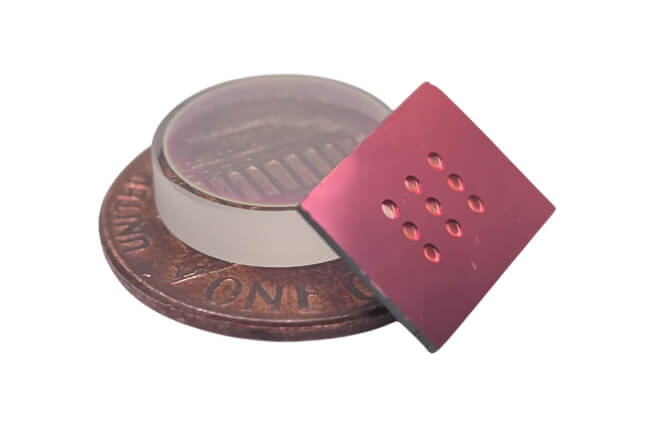

In a previous study, Fernandes and his colleagues found that the diagonally reinforced square grid-like system of skeletal struts (located beneath the surface ridges) of E. aspergillum had a higher strength-to-weight ratio than the traditional lattice designs that have been used for centuries in the construction of buildings and bridges.

Building on that research, the team developed a set of mechanical and computational fluid dynamics models to understand how the maze-like organization of helical ridges that surround the main skeletal tube of the sponge impacts fluid flow around the structure.

“From these models, we discovered that not only do these ridges provide additional mechanical reinforcement, but perhaps more significantly, provide a critical hydrodynamic benefit by effectively suppressing vortex shedding and reducing lift forcing fluctuations,” said James Weaver, a Senior Scientist at SEAS and the paper’s corresponding author.

In nature, this design helps the sponge stay anchored in the soft sediments of the sea floor. In engineering, it could help protect tall structures from wind damage.

The team compared the performance of the sponge’s maze-like ridge geometry to other more symmetrical vortex suppression systems commonly used in everything from antennas to underwater gas and oil pipelines and found that the sponge design outperformed them all.

Time-lapse video showing the production of 3D-printed models of the different equal-volume ridge designs explored in this study (the maze-like sponge geometry is shown in the middle). (Credit: Harvard Bok Center’s Learning Lab)

“Today’s approaches for reducing vortex shedding don’t actually prevent it from happening,” said Fernandes. “Rather, they simply shift the shedding to a more downstream location. In contrast, the sponge’s ridge design completely stops vortex shedding across a wide range of flow regimes.”

“This research could improve how we build cylindrical structures anywhere you need to control fluid flow to improve efficiency or reduce vortex-induced vibrations, including smokestacks, antennas, submerged piping, and offshore floating platforms,” said Katia Bertoldi, the William and Ami Kuan Danoff Professor of Applied Mechanics at SEAS and co-author of the study.

The Harvard Office of Technology Development has protected the intellectual property relating to this project and is exploring commercialization opportunities.

The research was co-authored by Mehdi Saadat, Patrick Cauchy-Dubois, Chikara Inamura, Ted Sirota, Garrett Milliron, and Hossein Haj-Hariri. It was supported in part by the National Science Foundation under grants DGE-1144152, DMR-2011754 and DMR-1922321.

Topics: Bioengineering, Design, Materials, Technology

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Katia Bertoldi

William and Ami Kuan Danoff Professor of Applied Mechanics

Press Contact

Leah Burrows | 617-496-1351 | lburrows@seas.harvard.edu