Eugene Beh, A.B./A.M. ‘09 (Quino Energy)

One challenge of building a large-scale energy grid around renewable sources is that when energy demand is low, solar and wind farms may need to either shut down or sell their electricity at a loss, even if the sun is shining or the wind is blowing. Alternatively, the availability of electricity from renewable sources diminishes when the wind calms or the sun goes down, leading to too much demand on the grid.

Flow battery storage systems are a way to balance out the market, allowing surplus electricity to be stored long-term and released during periods of high demand or low production. The Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has been at the forefront of organic flow battery research over the last decade, led by the labs of Michael Aziz, Gene and Tracy Sykes Professor of Materials and Energy Technologies, and Roy Gordon, Thomas Dudley Cabot Professor of Chemistry and Professor of Materials Science, Emeritus. Eugene Beh, A.B./A.M. ‘09, a former undergraduate and then postdoctoral researcher in the Aziz and Gordon Labs, has spun off some of that research to co-found Quino Energy, a start-up creating redox flow batteries that use solutions of molecules called quinones, dissolved in water, as the active material.

Quinones are a class of naturally abundant organic compounds found in a wide range of materials, organic dyes, and vegetables like rhubarb. When dissolved in water, quinones serve as a store of energy by undergoing oxidation or reduction reactions when passed through a device known as a flow battery stack. Because the Quino Energy active material is water-based, it won’t catch fire, and because it comes from an easily sourced organic compound, it’s much cheaper to produce than traditional active materials such as vanadium.

While the Harvard research groups had previously reported many long-lifetime, high-performing quinone battery reactants, Quino Energy has taken a big step towards turning the lab research into a viable commercial product: at the end of last month, the pilot production line for the quinone active material commenced operations and quickly achieved a full production rate of more than 20 kilograms of finished quinone per hour.

“It’s incredibly gratifying,” Beh said. “It’s really cool to see something go from the lab to a finished product and production line, and now we can start to produce something that makes a difference.”

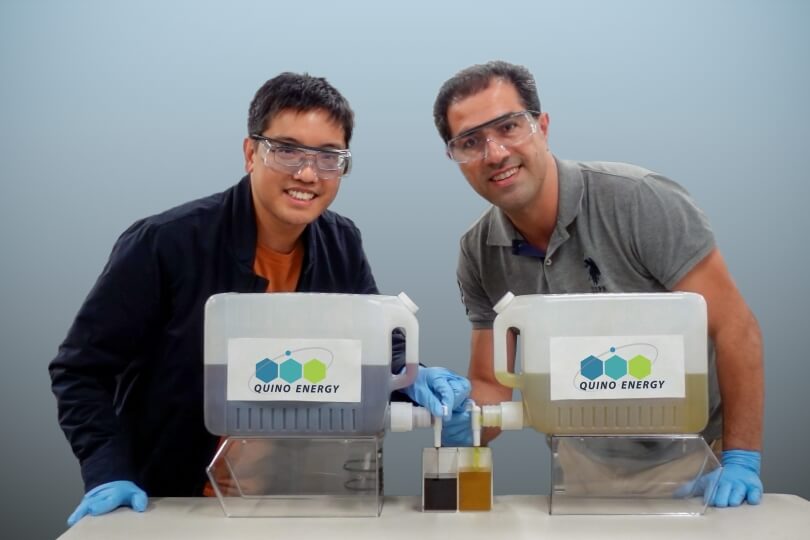

Quino Energy co-founders Eugene Beh, A.B./A.M. ‘09, and Meisam Bahari, a former postdoctoral researcher at SEAS (Quino Energy)

Once Quino Energy’s pilot line expands a further five-fold in the second half of 2024, Beh hopes it will be able to produce the quinone active material at a price on par with vanadium.

“We’ve been able to come down the cost curve fast because our pilot production line produces the finished active material in a single-step, zero-waste, continuous-flow process,” Beh said. “Vanadium production is dominated by China and Russia. This unlocks easy domestic production of battery materials, which has been a longstanding policy goal of the United States and the European Union."

Reaching this manufacturing milestone is the latest in a series of recent achievements for Quino Energy. The company received a $4.58 million dollar grant from the Department of Energy in June 2022 to support the development of its innovative production process and the construction of the pilot production line. Plans are already underway to use the active material in three pilot demonstrations, each capable of storing several megawatt-hours of energy. Utility-scale deployments, as large as hundreds of megawatt-hours, would likely break ground in 2026 or 2027.

Beh co-founded Quino Energy in 2021 with Meisam Bahari, who had also been a postdoc in the Aziz Lab. Aziz and Gordon both serve as co-founders and scientific advisors at Quino Energy. Harvard’s Office of Technology Development was responsible for protecting the background intellectual property and subsequently licensing it to Quino Energy for further development. The production process itself was jointly invented by Quino Energy and Harvard researchers.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu