News

For a senior capstone project, Brice Austin designed a liquid-filled window for more efficient heating and cooling of buildings.

Engineering Design Projects (ES 100), the capstone course at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), challenges seniors to engineer a creative solution to a real-world problem.

Development of a Platform for Large-Scale Liquid Windows

Brice Austin, S.B. ‘25, Mechanical Engineering

Advisor: Raphael Kay, Leonard Palmer

• Please give a brief summary of your project.

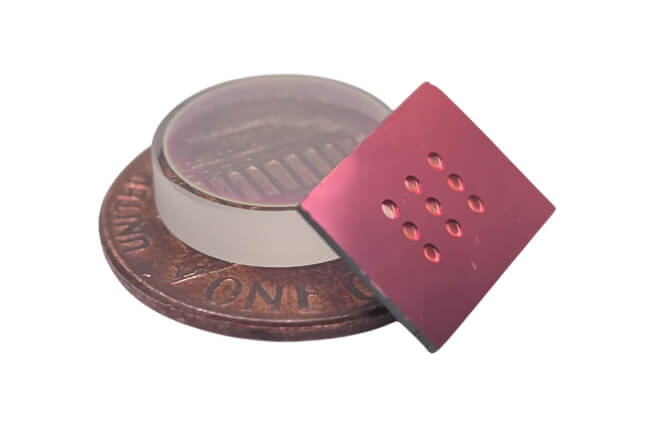

Buildings, specifically the maintenance of their internal temperature to a comfortable level, are a huge energy sink, accounting for approximately 25% of all electricity use in the U.S. annually. Windows are the biggest source of these energy losses. Liquid Windows is a technology that utilizes thin layers of fluids to modify light as it enters these spaces; in theory, the technology can provide shading, block out heat, scatter light, and modulate many other properties of light, something that other products who utilize solid state technologies struggle with. These layers can also be filled and drained, effectively turning layers on and off. If you're clever you can determine the best combination of fluids for every time of day and personal preference to create the optimal thermal and optical configuration, providing an aesthetic and energy-efficient solution with savings of up to 40% according to predictive models.

• How did you come up with this idea for your final project?

Initial research into the Liquid Window concept was conducted by Raphael Kay, a graduate student who is a member of the Aizenberg Lab at SEAS with the support of lab principal investigator Joanna Aizenberg.

• What was the timeline of your project?

I conceptualized the project in September, and began prototyping in October to understand the complexities of the system and what constraints may exist. I developed an intermediate-scale prototype in November to prove the concept on a reasonable scale, then began designing the full scale in January and February with improvements learned from the intermediate scale. I built a full prototype in March.

• What part of the project proved the most challenging?

Integration of all system components. Minimizing space was a priority so fitting every component into a reasonably small form factor was challenging. That and leaking, of course.

• What part of the project did you enjoy the most

Seeing the final product work. Many hours went into it and I think it is one of the most impressive projects in terms of scale and visual appeal. It conveys an idea that seems crazy and will hopefully attract attention to help us develop this more in the future.

• What did you learn, or skills did you gain, through this project?

Getting more comfortable with the difficulties of actually executing a project. It's a process I wish we were exposed to more in our education here because you truly learn how to plan effectively. You often make assumptions or design choices that come back to bite you; learning how to work through those and more importantly not make them in the future has been my biggest takeaway.

Topics: Academics, Materials Science & Mechanical Engineering

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu