News

Rayhaan Saaim attaches the rear suspension system to the FSAE chassis (Matt Goisman/SEAS)

Rayhaan Saaim and Edwin Dominguez were struggling to get the Harvard Undergraduate Automotive Society (HUAS) off the ground. Like a lot of Harvard’s student clubs, HUAS saw its membership greatly reduced due to campus restrictions on gatherings during the first two years of the pandemic. And because so few people were in the club, almost nothing got built, making it hard to advertise the club at the annual fall student organizations fair in Harvard Yard.

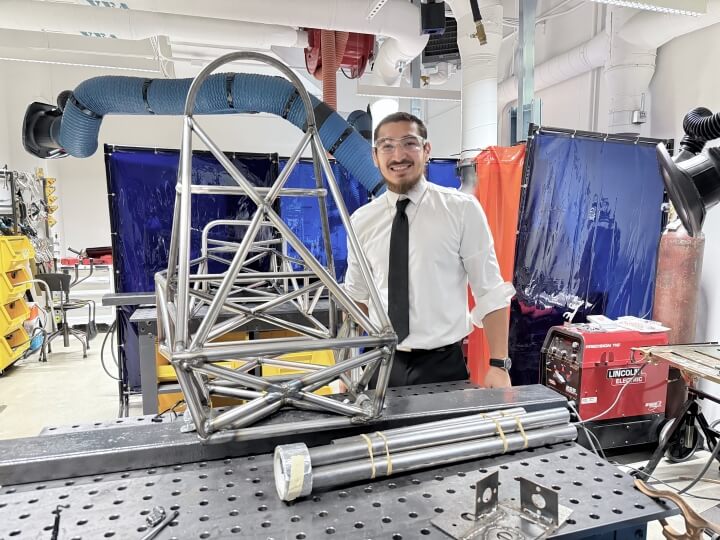

Edwin Dominguez with his FSAE racecar chassis (Matt Goisman/SEAS)

Saaim, Dominguez and three fellow fourth-year students at Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) found a way to kill two birds with one stone. Already working on components of a Formula-style race car for their senior capstone projects, the seniors decided to use the work they’d already done to advertise the project to prospective members. Once students started signing up and showing up to gatherings, they were tasked with working on other elements of the car as the seniors continued building their components.

“One thing we tried to emphasize is that as much as your classes are extremely important in terms of industry, you won't get industry-level experience out of those classes,” Saaim said. “There might be some small projects, but something where you're working with other people, you have systems that must work with other systems and be compatible, it's something that's unique, and I think a project like this brings it to another level.”

The end result: a quintet of senior capstone projects that within the next few years could lead to SEAS competing in Formula SAE, an intercollegiate design competition in which students design, present and race cars built in the open-wheel style of Formula One vehicles (as opposed to passenger cars, whose wheels are partially covered by the chassis). The competition is sponsored by SAE International, previously known as the Society of Automotive Engineers, and is unaffiliated with Formula One.

“You're tasked with making the fastest car you can that passes inspection, follows all the rules, and beats all the other cars,” Saaim said. “They do this because they want it to prepare students for work post-graduation, where you have to work with a team, you're given these criteria and constraints, and you just are tasked with presenting your work and making sure that you understand your work as well.”

Peter Fischer and Josh Gordon attach the drivetrain to the chassis (Matt Goisman/SEAS)

Jack Meyer designed the steering system for the FSAE project (Matt Goisman/SEAS)

DIVIDING THE LABOR

Five different capstone projects comprised the majority of work this year. Saaim designed the rear suspension, Dominguez built the chassis, Oliver Murcko and Steffan Jones worked on aerodynamics, Josh Gordon and Peter Fischer built the drivetrain, and Jack Meyer worked on steering and the front end of the vehicle. All four projects were advised by Erik Madsen, a manager at Harvard’s Rowland Institute with a background in automotive design and racing.

Their work was built on two capstones from 2024: Tommaso Serafin, who studied the validation of a Formula vehicle’s hybrid front suspension, and Carlos Gutierrez, who built an FSAE frame. Serafin also served as one of Saaim’s mentors, along with Tony Paganis, S.B. ‘22, the first SEAS student to work on an FSAE-focused senior capstone.

“Tommaso and Carlos, they were doing it just for their thesis,” Saaim said. “However, they were building it following all the rules, and their thought was that if we started a team, we could use their thesis product for the car. For this year, we had it in mind that we are doing all this for the same car. It's clear in our mind that we are doing this for the club.”

Oliver Murcko and Steffan Jones with their aerodynamic components (Matt Goisman/SEAS)

While the seniors worked on their components, underclassmen at HUAS worked on the electrical, engine, seating and safety components. Saaim and Dominguez made sure to document all the work they did this year, hopefully making it easier for the club to continue down the line. Now graduated, Saaim will also stay on as an advisor for the club.

“A key factor was building the foundation,” Saaim said. “There is still quite a bit of work to be done, but thankfully with the main infrastructure done, people can build on top of it. Once the car is completed and running, and two years down the line when it's brought to competition, I think what's gonna be great is we're going to have these thesis reports where students can just optimize our designs.”

THE CHALLENGES OF GROUP DESIGN PROJECTS

Designing components of a larger build presented unique challenges for the seniors. Saaim had to make sure any change he made to one element within the computer-aided design (CAD) files he created didn’t break the overall geometry of the rear suspension. For Dominguez, whose chassis will eventually house everything else, that challenge was even greater.

“As I went through my designs and found out what worked best for my specifications, I’d share those CAD files to everybody, just to make sure that their CAD files fit within it,” Dominguez said. “I had to keep the pace on my timeline a little further ahead of the other teams, just in case something had to be changed.”

Saaim and Dominguez cited multiple mechanical engineering classes as directly informing their capstone project, including “ES120: Introduction to the Mechanics of Solids,” “ES125: Mechanical Systems,” “ES128: Computational Solid and Structural Mechanics,” and “ES51: Computer-Aided Machine Design.” Combined with their work in HUAS, designing an FSAE car was the perfect way to bring together their four years at SEAS.

“Those are the main courses in the curriculum for mechanical engineering,” Dominguez said. “Implementing those in a big model like this pretty much summed up my time here.”

Topics: Academics, Materials Science & Mechanical Engineering, Student Organizations

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu