News

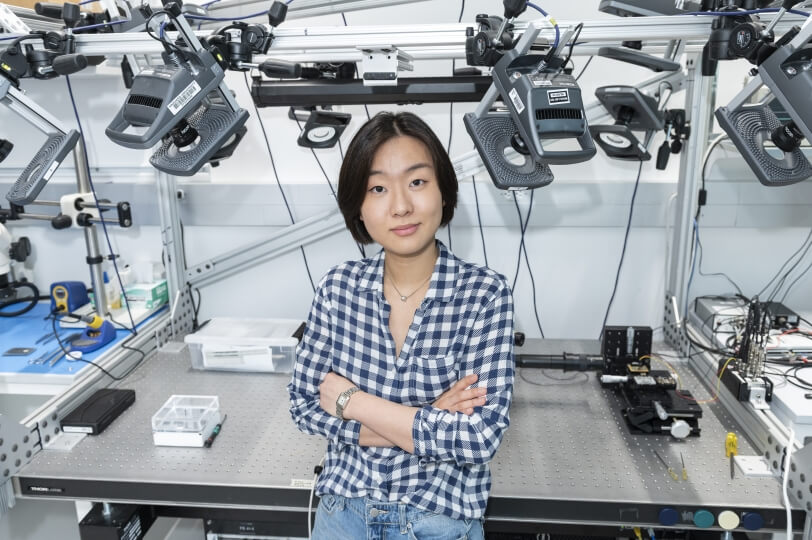

For her senior capstone project, Soy Choi designed a sensor system to allow robotic grippers to classify and continuously predict finger positions (Hertz Foundation)

Engineering Design Projects (ES 100), the capstone course at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), challenges seniors to engineer a creative solution to a real-world problem.

Capacitive Strain Sensor System for Soft-Rigid Hybrid Robotic Grippers

Soy Choi, S.B. ‘25, Mechanical Engineering

Advisor: Michelle Yuen, Robert Wood

• Please give a brief summary of your project.

I developed a capacitive strain sensor system for robotic fingers capable of detecting joint bending with high accuracy, relying on just a single electrical interface. The system combines low-cost, stretchable materials with a deep-learning framework to classify and continuously predict finger positions in real time. My work enables scalable sensing in robotic grippers, supporting applications in assistive technologies, industrial automation, and prosthetics. I also integrated a custom sensing workflow for real-time, embedded implementation.

• How did you come up with this idea for your final project?

The idea was inspired by my journey in golf. I started with a pair of inherited, worn-out clubs – and to my surprise, they took me to the top of my varsity team. I was so excited to finally get the latest custom-fit clubs for my birthday. But through tough losses, I realized that no matter how advanced the equipment, it means nothing without a strong grip. That insight stuck with me. I became fascinated by the power and finesse of the human hand — how much information it communicates through touch and control. This fascination led me to the Harvard Microrobotics Lab, where I began designing stretchable skin sensors to give robotic fingers that same proprioceptive awareness – the sense of “grip” I had to build in myself as a golfer.

• Is there a real-world challenge that this project addresses?

Many robotic systems today lack embedded proprioception – the ability to sense their own configuration without relying on external systems like cameras. This limits their ability to perform fine manipulation, especially in poorly lit or human-centric environments. My project addresses this by offering a low-complexity, low-cost sensing system that can accurately estimate joint angles in real time using a single electrical interface. It bridges a major gap in scalable, soft-rigid hybrid grippers and points toward future systems that can “feel” their own movements the way humans do.

• What was the timeline of your project?

In the fall, I completed early-stage inductance, capacitance and resistance (LCR) meter testing, characterized sensors in isolation before attachment to robotic fingers, and a proof-of-concept neural network. From November to January, I rebuilt and scaled the system to test across continuous bending states and over 1,000 mechanical cycles. In February and March, I finalized real-time sensing, completed embedded testing, and conducted advanced modeling. In March and April, I compiled all engineering documentation, performance evaluation, and final thesis writing.

• What part of the project proved the most challenging?

Integrating the sensing system into a real-time, embedded workflow was the most difficult. The LCR meter was extremely slow, and designing and validating an alternative while retaining high accuracy and speed required deep iteration and signal analysis. It pushed me to balance mechanical design, data processing, and modeling all at once.

• What part of the project did you enjoy the most?

Integrating the sensors and watching them work in real time – especially seeing my neural network predict finger shapes based on live capacitance – was incredibly rewarding. I also loved working closely with my mentor, Michelle Yuen, and learning from the many brilliant members of the Microrobotics Lab. The relationships I built made the lab feel like more than a technical space – it gave the work a bit of soul.

• What did you learn, or skills did you gain, through this project?

I learned how to take a complex, multidisciplinary project from concept to functional prototype. I gained skills in sensor characterization, computer-aided design, signal processing, embedded systems, and deep learning. More importantly, I learned how to design with empathy and user needs in mind: always thinking back to my own hands and my dad’s favorite golf phrase, “You’re only as good as your grip.”

Topics: Academics, Materials Science & Mechanical Engineering, Robotics

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu