News

ElectroStep team members Jerry Li, Viktor Bokisch, Kiyana Gallagher, Josefina Biernacki, Leah Lourenco, Ashley Redhead and Andrew Morrissey (Eliza Grinnell/SEAS)

We wear shoes all day, every day, sitting, standing, walking and exercising. And yet for so many people, the goal is just to get home, take them off, and rest their aching feet.

What if our shoes could actually help heal our feet? What if they were designed to relieve pressure, or even mimic certain forms of physical therapy?

Two teams of engineering students at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) became cobblers this semester, tackling the challenge of designing two new therapeutic shoe prototypes for New Balance Athletics. The 13 students developed their shoe prototypes for “ES96: Engineering Problem Solving and Design Project,” a core course for third-year students pursuing S.B. engineering degrees.

“Eighty-seven percent of people experienced foot pain at some point in their lives,” said Leah Lourenco, a team leader for one of the prototypes. “From reading this statistic alone, it became clear to our team that this is a key problem in need of a novel solution.”

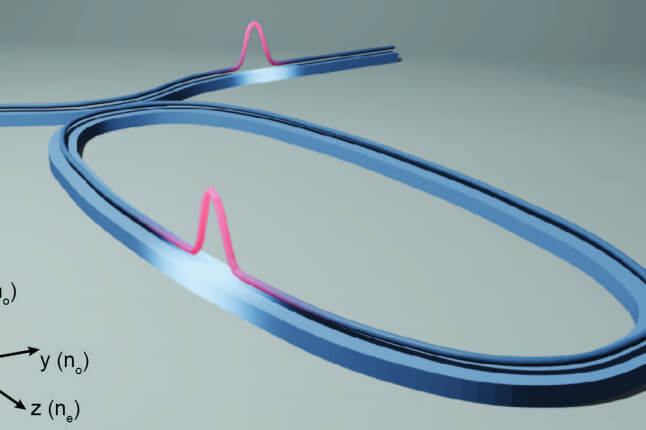

The two shoe prototypes developed for New Balance were called ElectroStep and Caelis. ElectroStep incorporates microcurrent electrodes into the sole of the shoe, facilitating a therapeutic practice known as microcurrent electrical neuromuscular stimulation (MENS). The current is subsensory, far below the threshold of potential pain or tissue damage, and it enables the wearer to experience potentially hours of physical therapy after working out.

“When we exercise, microscopic tears and muscle fibers initiate a biological pathway that leads to muscle regeneration and strengthening,” said team member Kiyana Gallagher. “Typically, when we exercise microscopic tears and muscle fibers initiate a biological pathway that leads to muscle regeneration and strengthening. MENS stimulation mimics this process by triggering those same regenerative pathways, enhancing muscle recovery and accelerating growth beyond what would occur through rest alone.”

Along with academic interest, Viktor Bokisch drew on personal motivation as he helped develop ElectroStep. Before attending Harvard, Bokisch served for six years in an infantry division of the U.S. Army, including one year of deployment in Afghanistan.

“We spent all our time on our feet,” Bokisch said. “Any time we were moving to a new place, we were walking. So lower-limb injuries are very commonplace for us, and foot soreness and foot debilitation are really common as well.”

Caelis team members Miranda Morales, Ayande Joseph, Thomas King, Jack Anderson, Mikaya Parente and Davina Komaravalli (Eliza Grinnell/SEAS)

Caelis, which means Heaven in Latin, was designed for medical professionals and hospitality workers who are on their feet all day. It incorporates specially designed pouches into different parts of the shoe. These pouches are filled with oobleck, a combination of water and cornstarch that exhibits non-Newtonian properties, meaning it hardens with additional pressure and softens with less. By placing these pouches in key areas such the heel, arch and balls of the feet, Caelis is able to reduce the pressure on some of the most common sources of foot pain.

“We had some of our survey respondents walk around for 5-10 minutes and tell us what they thought,” said Jack Anderson, part of the Caelis team. “One quote from them said, ‘I really noticed the non-Newtonian fluid in the pockets of the shoe. When I was walking and putting a lot of pressure on my feet, the pockets felt rigid. However, when I was just standing, it conformed to my foot.’ This was really gratifying for us to see, because it demonstrated that the non-Newtonian fluid was working and that it actually served its purpose.”

ES96 is a unique experience within the SEAS curriculum. Most students won’t have previously worked on a class project of this size – ElectroStep had seven members, Caelis had six. And while most higher-level SEAS courses are geared toward one specific concentration, ES96 deliberately mixes in students from all four engineering concentrations: electrical, mechanical, bioengineering, and environmental.

“We got to integrate a lot of different technology and skills to make our products, which was great,” said Thomas King, who led the Caelis team. “The soft skills of being in a room with 13 people, where we all have ideas that we want to contribute, making sure everyone feels like they have the space and their ideas are valuable, was such an invaluable experience to have.”

Added Lourenco, who led ElectroStep, “There’s really a whole other vocabulary that designers use that I was unfamiliar with coming into the class. Through the last couple months, I’ve gained a design vocabulary that has greatly enhanced my senior capstone proposal, and I’m sure will benefit me in my career.”

ES96 is also as much about learning how to solve a problem as it is about actually solving it. The early weeks of the class focus on research, and prototyping a solution doesn’t begin until the students can clearly describe the problem they want to solve, and what a successful solution would actually achieve.

Course instructor Alexandros Haridis, Lecturer on Engineering Design at SEAS, said he picked New Balance as a client because he wanted his students’ industry partner to make products they were familiar with from their daily lives.

“I was very impressed with the way the students managed to define the problem, find something that personally interested them, and put it together in a very interesting way,” Haridis said. “Trying to apply a design methodology that balances their university education and industry requirements was a very interesting and realistic process.”

Working with a client also sets ES96 apart. Teams had to provide status updates every two weeks, and New Balance representatives were on hand every time to provide feedback and direction.

“At the beginning of the semester, I said the students could pick one of our problems, or go their own way,” said Onur Yüce Gün, Director of Computational Design at New Balance and industry representative for the class. “Each of them decided to go their own way, and I think that’s the true innovation mindset. They were able to not only propose questions, but also bring their skills, understanding and new learning to propose solutions.”

Topics: Academics, Materials Science & Mechanical Engineering

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Matt Goisman | mgoisman@g.harvard.edu